The art of cartridge game restoration has quietly persisted as a niche yet vital craft in the gaming preservation community. Among its most fascinating aspects lies the delicate practice of trace repair—an almost surgical approach to reviving damaged connections on decades-old circuit boards. This knowledge, once the guarded secret of a handful of arcade technicians and Nintendo repair specialists, now faces both unprecedented demand and alarming risk of being lost forever.

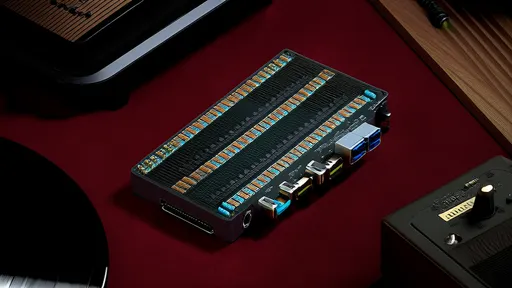

In dimly lit workshops across Osaka, Kyoto, and Tokyo, aging masters still demonstrate techniques that would make most electrical engineers pause. The process begins with identifying broken "golden fingers"—the contact points along a cartridge's edge connector. Years of insertion and removal wear down these fragile traces, while corrosion from humidity and oxidation silently eats away at their conductivity. What separates true craftsmen from hobbyists is their ability to diagnose whether a game's failure stems from ROM chip degradation or simply interrupted pathways.

The tools of the trade appear deceptively simple: high-magnification headset lamps, conductive silver pens with needle-fine tips, and custom jigs to hold cartridges at precise angles. Yet their application requires years of muscle memory development. Veteran repairer Hideki Shimamura recounts his seven-year apprenticeship under a former Nintendo subcontractor: "We'd practice on destroyed Famicom carts until our hands stopped trembling. One micron of excess conductive paint could bridge adjacent circuits and ruin everything." This precision becomes especially critical when working with rare prototypes or one-of-a-kind arcade boards where replacement PCBs simply don't exist.

Modern technology has introduced both solutions and complications to the field. While USB microscopes and multimeters with ultra-fine probes assist in diagnostics, many purists argue they create a false sense of security. "Young technicians rely on digital readouts without understanding the analog soul of these circuits," laments Kyoto-based restorer Mariko Endo. She maintains that the most reliable test remains connecting repaired cartridges to original hardware and listening for the distinct startup chime of successful contact.

A surprising renaissance has emerged through online communities where specialists now share once-secret methods. Detailed photographic guides for repairing specific cartridge models circulate alongside warnings about inferior conductive paints that degrade within months. The most valuable contributions often come from retired engineers who worked on 1980s gaming hardware, revealing factory specifications for contact resistance that were never published. This open-source approach has enabled a new generation to preserve games that would otherwise fade into obsolescence.

The economics of preservation create constant tension. Commercial services offering cartridge repairs struggle to charge rates that reflect the hours of meticulous labor involved. Meanwhile, wealthy collectors increasingly hoard knowledge by purchasing rare service manuals and tools as display pieces rather than working artifacts. Some conservators have begun creating "time capsule" kits—sealed containers containing all necessary materials and instructions for future generations, to be opened only when current stocks of vintage conductive materials expire.

Perhaps the most poetic aspect of this craft lies in its philosophical implications. Each repaired trace represents not just electrical continuity, but cultural continuity. When a Master System cartridge that hasn't booted since 1991 suddenly displays its title screen again, it completes a circuit across time itself. The artisans performing these micro-welds and conductive brushstrokes have become unlikely guardians of play history, one golden connection at a time.

Looking forward, the field faces both challenges and opportunities. Museum conservation departments have begun collaborating with game collectors to establish standardized preservation techniques. Universities in Germany and California now offer courses combining materials science with practical cartridge repair sessions. Yet the clock ticks louder each year as original hardware components become more scarce and the last generation of factory-trained technicians reaches retirement age.

The ultimate test may come from an unexpected quarter. As retro gaming's popularity surges, counterfeiters have grown alarmingly sophisticated at replicating cartridge exteriors while failing to properly emulate the conductivity specifications of authentic boards. This has inadvertently made trace repair experts the frontline detectives in authentication cases, using their knowledge of period-correct materials and manufacturing techniques to spot fakes. Their ability to recognize authentic wear patterns on contact points has become as valuable as any museum curator's eye for brushstrokes on a painting.

In backrooms at gaming conventions worldwide, these specialists continue their quiet work—not merely fixing broken objects, but maintaining the physical infrastructure of cultural memory. The glow of their magnifier lamps illuminates something larger than copper pathways: it's the ongoing story of how we preserve the artifacts of human creativity when the original creators have long since moved on. Every repaired cartridge becomes a testament to the idea that technology, at its heart, remains a profoundly human endeavor.

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025

By /Jul 29, 2025